SOLAR LOW-E COMFORT

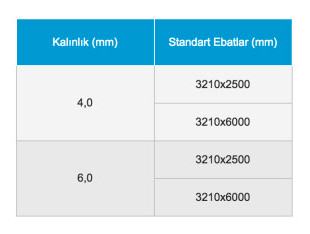

The dimensional tolerances are ± 5 mm for all the rated size. The demand for different sizes and thicknesses should be consulted Sisecam Flat Glass.

Housing in small and medium-sized preferred Sisecam Solar Low-E glass in commercial buildings,

heat and solar control feature comfortable living areas with offers to users.

Solar Low-E glass is the Sisecam Flat Glass heat and solar control glass.

- with a single coating provides solar control and thermal insulation together.

- Reduce fuel costs and air conditioning.

- Transparency and will not budge from natural daylight.

- Fog delays that occur on the glass surface.

- the front window in the winter cold, summer prevents the heat.

- causes discoloration of the articles and fabrics with ultraviolet (UV) radiation reduces the permeability of 91%.

- Compared to ordinary double glazing, solar Sisecam Low-E insulating glass produced using the glass you’ll spend for K returns with 1-2 years of savings for heating and cooling costs.

Sisecam Solar Low-E glass is the Sisecam Flat Glass heat and solar control glass.

Insulating Glass Manufacturers Authorized (II) by Sisecam Solar Low-E double glazing units manufactured using glass, insulating glass is presented to the market with the brand K Series Systems.

Our country is experiencing one of the four seasons, Sisecam Solar Low-E glass made with Insulating Glass Systems Series K, 77% heat loss compared to single glass, and by ordinary double glazing in winter fuel costs by reducing 50%; solar heat input saves 40% in summer cooling costs by reducing ordinary double glazing.

Şişecam Solar Low-E glass, flat glass in a vacuum by electron scattering method on a thin metal / metal oxide layer line obtained by application of non-coated

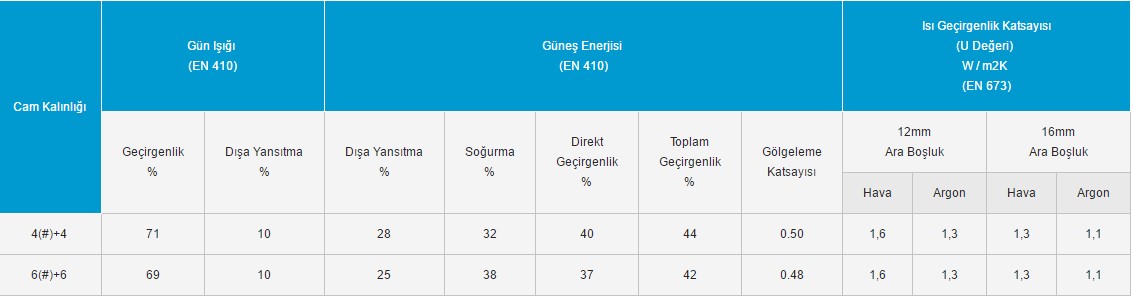

“Daylight” and “Solar Energy” values, using spectral data measured in the laboratory according to EN 410 standard, “TNO Science and Industry” – is calculated at 3:01 WISE software package.

The value of the thermal conductivity coefficient was calculated according to standard EN 673 with WIS 3.01. Emissivity values used in each account, in vitro EN 673 (Appendix A) and measured according to EN 12898.

exposure to solar radiation throughout the surface of the glass piece, the temperature differences between day and night, because of factors such as heat absorption coefficients of the glass of the sexes may arise or chopping risk of thermal breakage. Depending on these factors require the use of tempered or partially tempered glass. This document does not have any calculation for thermal breakage risks. For questions regarding this matter please contact Sisecam Flat Glass.

This document is for informational purposes only and the information they contain can be changed by Sisecam Flat Glass without any warning.

In this document the differences between the actual value depending on the conditions of the place of use with a given value may occur. Because of these differences Sisecam Flat Glass in no way be held responsible.

Daylight Permeability is the percentage of the light from the window glass.

Daylight Mirror (external): The percentage of incoming light reflected back by the window glass.

Total Solar Energy Transmission: Glass is the percentage of the total incoming energy from the sun. Lower total solar energy transmittance value, the better the solar control.

Shading Coefficient: Solar energy is compared to the total permeability of 3 mm colorless. The lower shading coefficient means better solar control.

Thermal Conductivity: a measure of thermal insulation in windows. The lower the value, the better the thermal insulation, heating costs and less means more winter comfort.

- Şişecam Solar Low-E glass transporting, storing, cutting and washing requires special attention.

- Human sweat and oil that coated glass can easily break the surface of the coating, coated glass using absolutely clean oil and sweat-proof gloves should be worn. Bare glass should not be handled in any way. Must be replaced immediately contaminated gloves and lubricated. reusable washing and drying the wet with sweat.

- Coated glass was laid on the table should be noted that the uncoated cutting surface, the cutting should always be so coated. The lens must be kept on the surface coated with the suction cup when tilting the table. Solar Low-E glass products in Sisecam is not recommended to be done by hand cutting. Never use essential oils in the cutting machine.

- Şişecam Solar Insulating Glass Low-E Glass F Series made by coating the insulating glass unit in the region of the edges along the periphery of the coated glass must be completely stripped until 10 mm.

- Şişecam Solar Low-E glass should be washed with a soft brush. conductivity wash 30 s / cm was purified exceeding (demineralised) water should be used.

- Cut Şişecam Solar Glass Low-E insulating glass should become my latest within 1 day.

- Insulating Glass Systems K Series, Sisecam Solar Glass Low-E coated side of the unit (2 sides) must be produced to remain.

- Off-line coating technology produced by Sisecam Solar Low-E glass, when the fulfillment of the following storage conditions, can be stored for 6 months.

- Sisecam Solar Low-E glass after handling the package should be careful not to be opened before reaching the factory ambient temperature. (Factory setting temperature did not reach the unpacking may cause deterioration of moisture condensing on the coating between the plates.)

- If the package front and rear of the outer surface condensation is detected, the result tapes opening condensation in the package is folded, this water must be removed to prevent water from entering into the package formed and the glass wiped dried. Then the package must be opened.

- plates until the cutting step, the packaging material on the package or stack of glass must not be removed.

- Factory ambient temperature must not fall below 15 ° and should be avoided Storage in the vicinity of the door.

- Factory, business and transportation areas should be free of corrosive fumes. (Hydrochloric acid etc. Matter of caution is required not to store the same place.)

- After şişecam guard bands at the edges of the solar Low-E glass products removed humectant on the glass should be such that no residue remains. If the humectant to remain longer on the plate, moving, cutting, escapes between the glass plates during processing and cause the glass to be drawn. Because of the protective tape burnt into the uncoated side it can be cleaned with glass cleaner or ethyl alcohol.

- Sisecam Solar Low-E glass products in; opened stack and packages to be sealed with the protective tape placed desiccant pack. opening before closing one of the desiccant dehumidifier color must be checked, if the color turns from blue to pink desiccant dehumidifier must be replaced.

Get Information for Your New Project

Feel the difference of experienced team and corporate experience