ISICAM SYSTEMS K SERIES

Thickness and Standard Dimensions

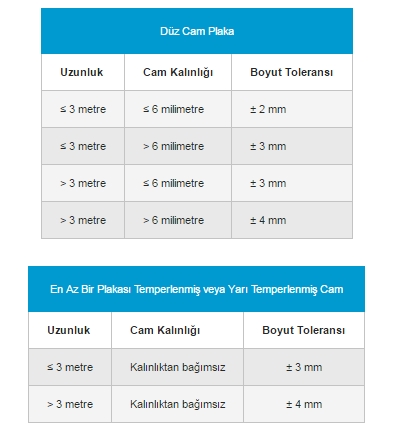

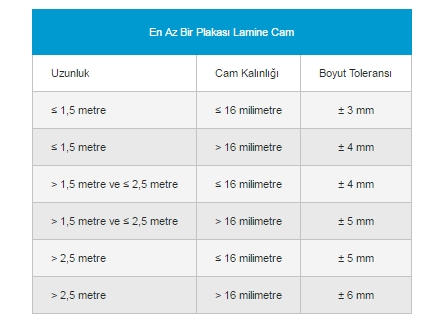

Pane windows of the dimensional tolerance (according to EN 1279 ‘a)

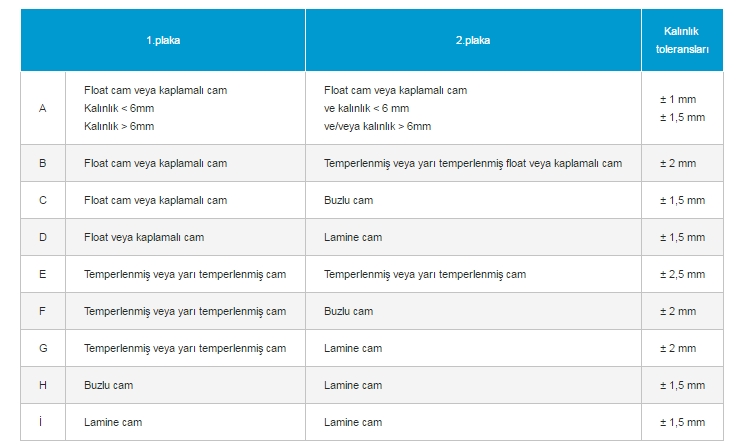

Insulating Glass unit thickness tolerances

misalignment tolerance between the insulating glass unit plates

shift amount between the lower and upper glass pane windows forming plate may be up to 1.5 mm.

Processing and Applications

Isıcam edge features

- The edges of the glass should be cut straight and there should not be any notches or flakes on the glass. Thermal voltage etc. In order to reduce the risk of breakage and cracking, it is recommended that the deburring process is carried out on the laminated glass.

- Sealant (butyl) It should be especially smooth and continuous, including at the corners. On both sides of the profile butyl weight 2,5 g / m should be. The pressed unit butyl width should be at least 3 mm.

In gas filled unit butyl weight profile on both sides of at least 3, 0 g / m must have its width in the compressed unit must be at least 4 mm. - And insulating paste binder polysulfide (Thiokol) / silicone / poliüretanprofil be slipped into the edge of the unit. Thiokol / polyurethane gap of at least 3 mm and the gap of silicon is at least 6 mm. Structural Glassing used in dual-pane windows, set out in the project design criteria are applied.

In gas-filled cavity unit Thiokol or polyurethane should be at least 4 mm. - Spacer bar (profile) for acceptable deflection profile strip size up to 1 meter up to ± 1 mm is at most ± 2 mm size strips to more than 1 meter. Distance to the glass edge, looking out into the profile of the unit should be a maximum of 15 mm. Structural Glassing used in dual-pane windows, set out in the project design criteria are applied.

It is recommended to use twisted profile in the gas-filled unit. If they cut profile used in the corners of the clip the clip enters the profile above (the surface in contact with the outer sealing paste) it should be closed in an amount of butylated. - Sıyırmalow edge-E, Solar Low-E glass coated with such soft while manufacture of insulating glass, coated glass of the edge; made of polyurethane or polysulfide production be 10 mm, 13 mm wide edge deletion is to be made with the silicon production process should be performed.

The newly built or renovated with solar control glass used in residential and commercial buildings.

Which should be used in Insulating Glass which region?

According to the climatic conditions in your area by selecting your Isıcam’ı can provide the most accurate and efficient insulation.

Ordinary double glazing compared to 50% of heat loss in winter, reducing fuel costs, reduce solar heat input to the inside of the summer air-conditioning costs and reducing 40% energy savings.

- While heat and solar control, without sacrificing transparency and natural daylight.

- The front window of the winter cold, summer heat and also prevent fogging delay compared to ordinary double glazing.

- you’ll spend for K Isıcam compared to ordinary double glazing, returns in 1-2 years with the savings you will provide the fuel and air conditioning costs.

Definition

Insulating Glass Systems K Series is manufactured with high-quality solar thermal and solar control coated Low-E Glass Sisecam. Maximum thermal insulation and solar control by providing winter fuel, reduce your air conditioning costs in summer.

Insulating Glass Systems, produced by Sisecam Flat Glass audited regularly by the Insulating Glass Manufacturers Authority.

Isıcam brand in production;

- Window and door proper quality and amount of materials are used,

- constantly under appropriate conditions of production and assurance that is carried out by using modern technologies.

Insulating Glass Systems, it Insulating Glass for 10 years against manufacturing defects originating from the authorized manufacturer is guaranteed.

Ek Özellikler ile Isıcam’ınızı Kişiselleştirin

Isıcam KL:

providing heat and solar control Sisecam Solar Low-E glass with safety and security providing Sisecam Laminated produced using glass insulating glass units, fuel and prevent injuries that can occur, preventing the dispersion breaking the glass in addition to the savings it provides to air conditioning costs.

Isıcam K AL

heat and solar control which Sisecam Solar Low-E providing noise control with glass produced using Sisecam Acoustic Laminated Glass Insulating Glass Unit, fuel and additional savings provided by the air conditioning costs as reduce noise transmission by providing sound insulation, Sisecam Laminated Glass’s safety and also it has a security feature.

Isıcam KT:

Sisecam Tempering Low-E glass can provide the safety Solar (thermal and solar control glass) is produced using. Because small and blunt pieces when broken left reduces the risk of injuries is suitable for use as safety glass. Heat and air conditioning provides maximum fuel-saving and solar control properties.

Isıcam M 3+:

a triple insulating glass units for maximum insulation. It provides four times by ordinary thermal insulation double-glazing.

Insulating Glass Systems, manufactured by Şişecam float and / or selling is made of two or more of the dry according to atmospheric pressure, between the glass plate of air or gas in insulating glass unit formed by bringing together under factory conditions to accommodate.

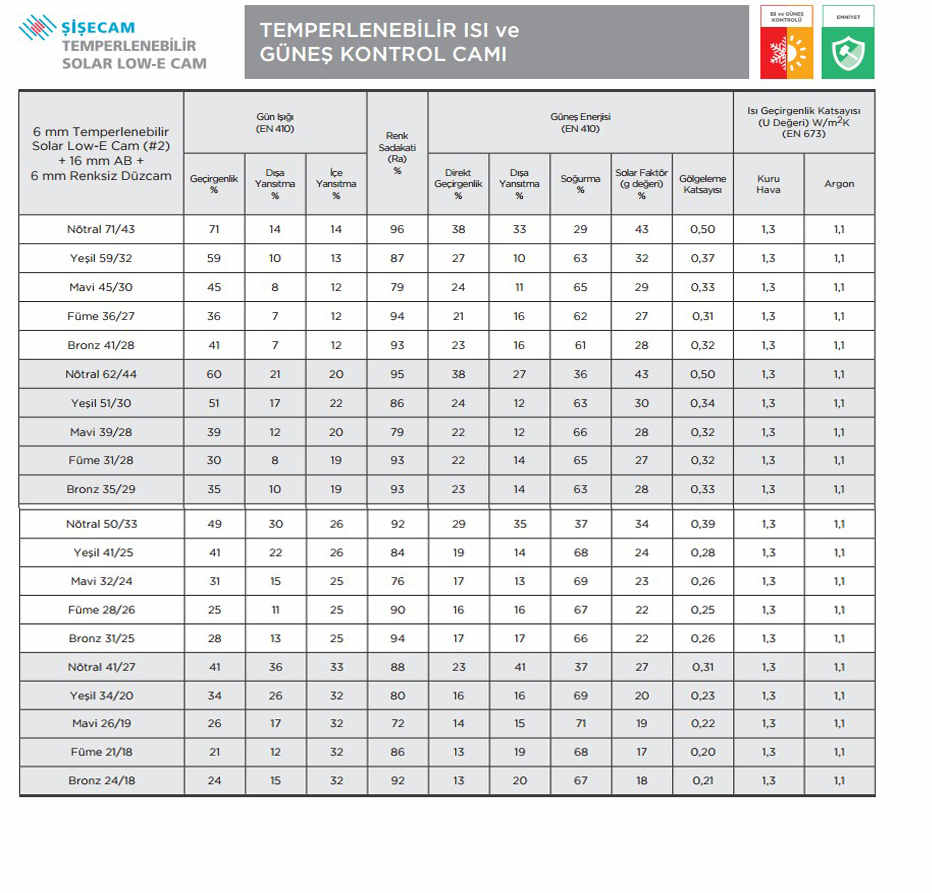

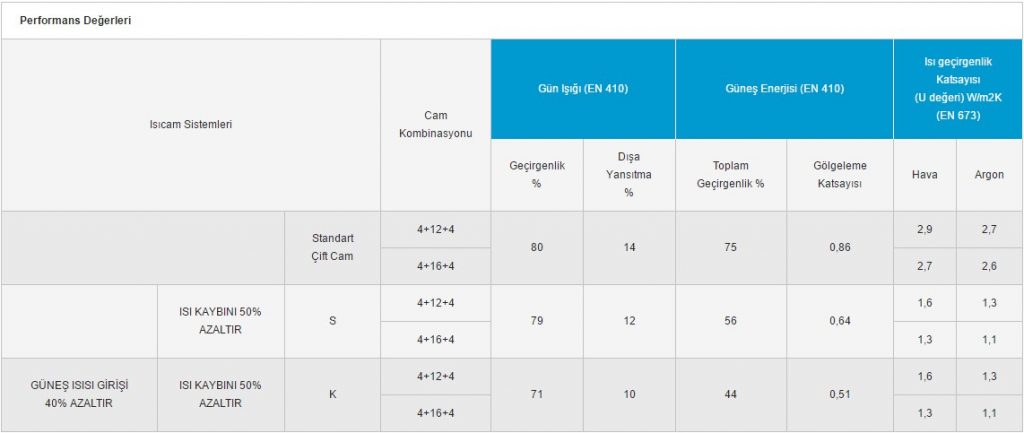

Performance Table

Rules Standard TS 825 Thermal insulation for buildings in the new recommended Up = 2.4 W / m² K value (glass windows + chopping, heat transmission coefficient), and can be reached with Insulating Glass Insulating Glass S K.

Insulating Glass Insulating Glass is located in the S and the inner surface of the outer glass coating K.

The dual-pane windows that are appropriate National / International Standards

TS EN 1279 3539 Glass – Used in Buildings – Based Insulating Glass Units

The National Register of Appropriate Raw Materials / International Standards

- Pine

- Float EN 572/2

- glass in market supply and final cut sizes EN 572/8

- Frosted EN 572/5

- Tempered EN 1215

- Partial tempered EN 1863

- Lamine EN ISO1254

- Coated EN 1096

- Heat bathroom tempered glass EN 14179

- Other Raw Materials

- In the insulating glass production; By Insulating Glass Flat Glass butyl şişecam prepared in the Approved List of Materials, polysulfide (Thiokol), silicone, polyurethane, dehumidifiers and gap bar (profile) is used. the sealing material used if the sealing material provided Isıcam replaced with another brand located in the Approved List of Materials, 3539 TS EN1279-4 standard conditions must be fulfilled substituents mentioned in item 4.2.2.

Isıcam Quality

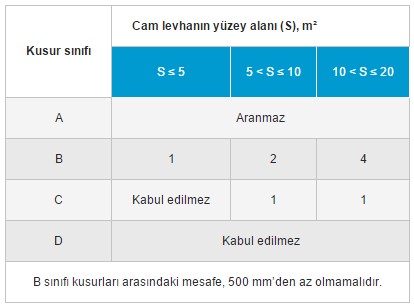

- Optical-pane windows and Appearance Quality

- Point Defects Pane windows of the optical and visual quality EN 1279 / is defined in claim 1. Accordingly pane windows forming optic in the corresponding standard glass and appearance quality appearance and quality status of geçerlidir.tek plates, insulating glass can be permitted in the unit is at a level that exceeds the maximum error limit is no need to search additional requirements relevant in this regard. However, a higher level of acceptance, in the customer and the quality of agreement between the insulating glass unit manufacturer places alabilirısıcam natural structure and / or caused by physical characteristics of optical and detailed information on the appearance quality EN 1279/1 Annex C verilmiştir.ısıca I ‘EN 572/8 in point defects as market supply and acceptance levels are applied to the glass in the final segment size is valid.

Point Defects Groups

- Produced by Sisecam Flat Glass and / or sales of Solar Low-E, Low-E, in-line produced by solar control coated glass coating in the insulating glass unit, the TS tolerances in EN 1096 Coated glass is standard applies.

- Linear (drawing and erasure) Defects Pane windows of the optical and visual quality EN 1279 / is defined in claim 1. Accordingly pane windows forming optic in the corresponding standard glass and appearance quality appearance and quality status of geçerlidir.tek plates, insulating glass can be permitted in the unit is at a level that exceeds the maximum error limit is no need to search additional requirements relevant in this regard. However, a higher level of acceptance, in the customer and in the quality of agreement between the insulating glass unit manufacturer alabilir.ısıcam natural structure and / or physical property information for the optical and visual quality caused by EN 1279/1 is given in Appendix C. ts EN 572/8 glasses in market supply and final segment size does not allow any linear defect as mentioned in the standard. EN 572/8 and the last segment of the market to supply the standard size glass in the determination of both surface defect observation point on the observation from a distance of 2 m Isıcam standards Although given shall be taken as 1 m. EN 1096 and EN 572/8 hence defects in said pharmaceutically acceptable error, as determined by observation from 1 m.

- Other DefectsAs known, the separator material interposed between the glass plates (lusitana powder, paper etc.) prevents friction with each of the glass maintains the glass surface against humidity and temperature changes. As a powder or paper characteristics interposed between the glass, the composition will not damage the chemical structure is not used any dust or paper. chemical structure as the grain size of the powder used is very important. Therefore it is specially recruited notes and powder to be interposed between the glass and controlled to be formed by the friction of kullanılmaktadır.ca plate in pinpoint worn of airborne moisture condensation or the chemical structure of glass by wetting degradation as a result of corrosion failure occurs. Corrosion failure is seen as white spots in the glass at an advanced stage. In the initial stage it can not be seen with the naked eye. Therefore, next time when the distance on the glass by the method of keeping the steam must be checked for corrosion starts. In insulating glass units are not allowed to corrosion failure. Therefore, attention must be paid to storage and transport of the glass package. When the glass packages shown in particular winter pack temperature, until the package is opened to ambient temperature işlenmemelidir.ar cavity facing the glass plate in the dust, washing pastes, fingerprint, etc. There must be no. at ambient temperature until the package is opened işlenmemelidir.ar cavity facing the glass plate surface dust, washing pastes, fingerprint, etc. There must be no. at ambient temperature until the package is opened işlenmemelidir.ar cavity facing the glass plate surface dust, washing pastes, fingerprint, etc. There must be no.

Get Information for Your New Project

Feel the difference of experienced team and corporate experience