CLEAR FLOAT GLASS

Şişecam clear float, edging, bending, tempering, partial tempering, laminating, coating, double glazing, secondary processes applying safety and security glass such as mirroring, temperature control glass, solar control glass, noise control glass, thermal and solar control glass, decoration It used as glass.

Sisecam secondary operations with added functions thanks to the clear float construction, decoration, automotive, white goods, agriculture, in many sectors, such as energy usage is provided.

Colorless Sisecam Flat Glass is the basic product for all glass applications.

Advantages

- TECHNOLOGY thanks to the production of high quality.

- Basic product for all glass applications.

- Thanks to the transparency has a high light transmittance.

- in different sizes and thickness, it is continuous and uninterrupted supply of existing facilities.

- It spreads to every corner of Turkey has an extensive distribution channel.

Definition

- Colorless Sisecam Flat Glass is the basic product for all glass applications.

- Şişecam clear float glass insulation products by applying to the secondary treatment unit, laminated glass, tempered glass, partly tempered glass, enamelled glass, curved glass, coated glass, mirror and colored glass can be produced.

- Sisecam Flat Glass, produces high quality float glass and flat glass production in the float with world-class technology.

- Flat glass (float glass), the glass melt obtained by the method floated on molten tin.

Float Glass Production of

flat glass production with float technology is implemented as follows:

Sand, soda ash, especially limestone, glass raw material blend containing a mixture of certain characteristic amount is melted at about 1600 ° C in an oven. Glass melt was about 1100 °, is poured into the molten tin pool oven and glass, by the floated on the tin, the two sides of guaranteed to be accurate and parallel to each other, and the thickness of the glass and strip width is formed. voltages in the tin pool of glass in a continuous manner within the cooling zone in a controlled manner by reducing the temperature of the glass ribbon is removed. Subsequently, the glass is collected in the package by cutting in desired size at the cutting line, and made ready for despatch.

Float glass, architecture and basic products for automotive purposes the use of glass and as available by the fact that the production line, the laminating order to improve the basic properties, tempering, coating, after passing through different processes such as mirroring can also be introduced. In this way; According to need, the heat and sound insulation, sun provides control, impact-resistant, is converted into a safe and a decorative material.

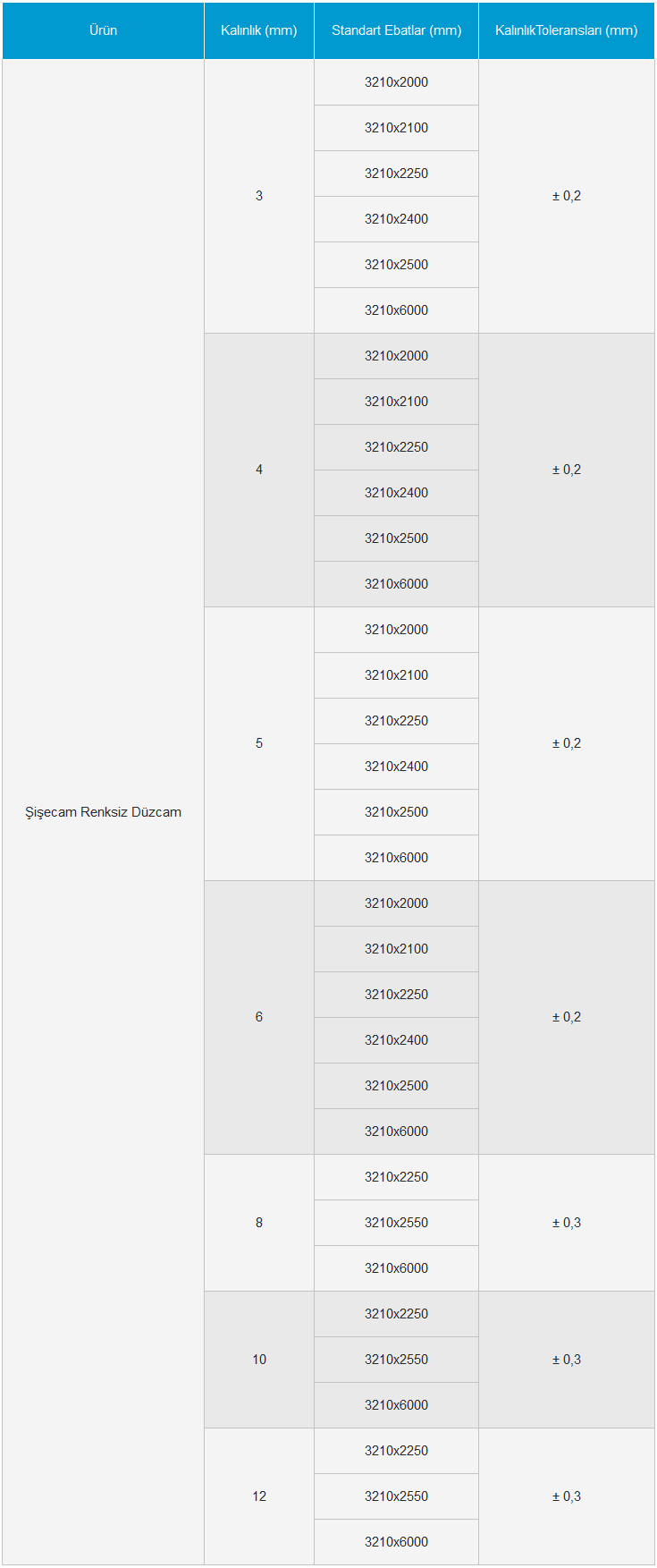

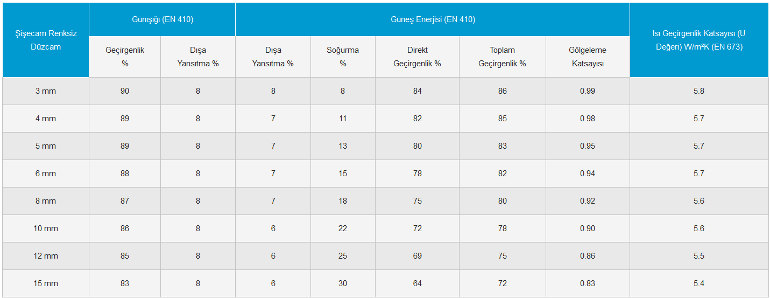

Performance Table:

“Daylight” and “Solar Energy” values, using spectral data measured in the laboratory according to EN 410 standard, “TNO Science and Industry” – is calculated at 3:01 WISE software package.

The value of the thermal conductivity coefficient was calculated according to standard EN 673 with WIS 3.01. Emissivity values used in each account, in vitro EN 673 (Appendix A) and measured according to EN 12898.

exposure to solar radiation throughout the surface of the glass piece, the temperature differences between day and night, because of factors such as heat absorption coefficients of the glass of the sexes may arise or chopping risk of thermal breakage. Depending on these factors require the use of tempered or partially tempered glass. This document does not have any calculation for thermal breakage risks. For questions regarding this matter please contact Sisecam Flat Glass.

This document is for informational purposes only and the information they contain can be changed by Sisecam Flat Glass without any warning.

In this document the differences between the actual value depending on the conditions of the place of use with a given value may occur. Because of these differences Sisecam Flat Glass in no way be held responsible.

Daylight Permeability is the percentage of the light from the window glass.

Daylight Mirror (external): The percentage of incoming light reflected back by the window glass.

Total Solar Energy Transmission: The total percentage of incoming solar energy is coming on the glass. Lower total solar energy transmittance value, the better the solar control.

Shading Coefficient: Solar energy is compared to the total permeability of 3 mm colorless. The lower shading coefficient means better solar control.

Thermal Conductivity: the glass is a measure of thermal insulation. The lower the value, the better the thermal insulation, heating costs and less means more winter comfort.

Get Information for Your New Project

Feel the difference of the experienced team and corporate experience